Professional Approaches for Preventing Weld Undercut Effectively

Professional Approaches for Preventing Weld Undercut Effectively

Blog Article

Grasping the Art of Welding: Just How to Avoid Undercut Welding Issues for Flawless Manufacture Results

By comprehending the root triggers of undercut welding and applying reliable techniques to avoid it, welders can raise their craft to brand-new degrees of quality. In the pursuit of perfect fabrication results, mastering the art of welding to prevent undercut issues is not simply a skill however a requirement for those making every effort for perfection in their job.

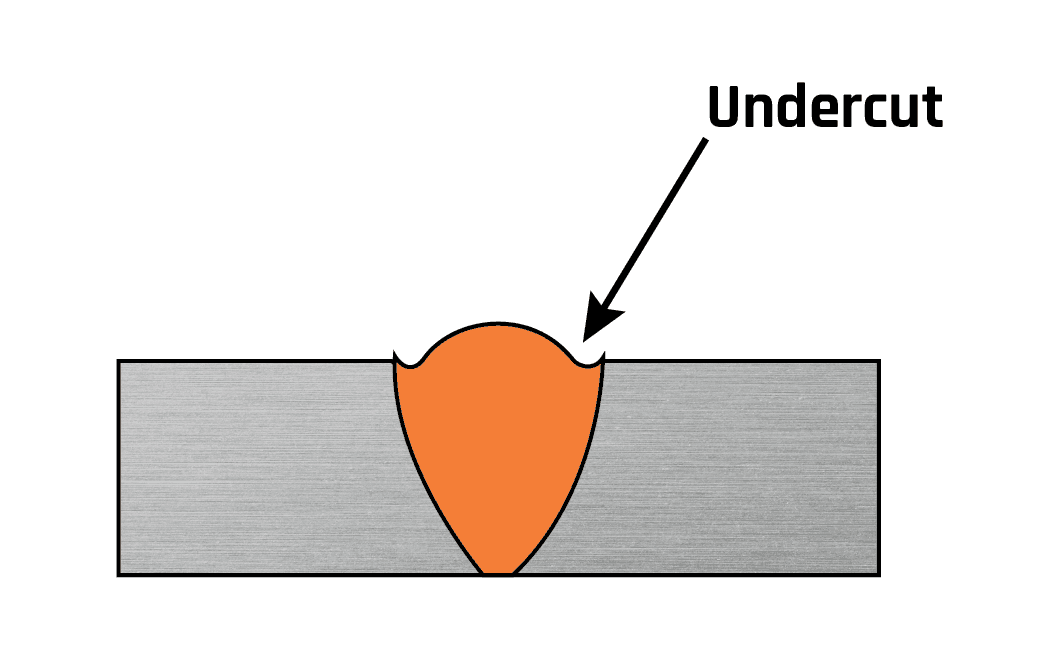

Comprehending Undercut Welding

To prevent undercut welding, welders ought to make sure appropriate welding criteria, such as readjusting the existing, voltage, traveling rate, and preserving the correct electrode angle. By comprehending the reasons of undercut welding and carrying out precautionary steps, welders can attain top notch, structurally sound welds.

Reasons of Undercut in Welding

Understanding the factors that contribute to undercut in welding is essential for welders to produce top notch, structurally sound welds. Poor welding wrong or existing welding rate can likewise contribute to damage. Comprehending these causes and implementing proper welding techniques can aid avoid damaging problems, making sure strong and long lasting welds.

Methods to stop Undercutting

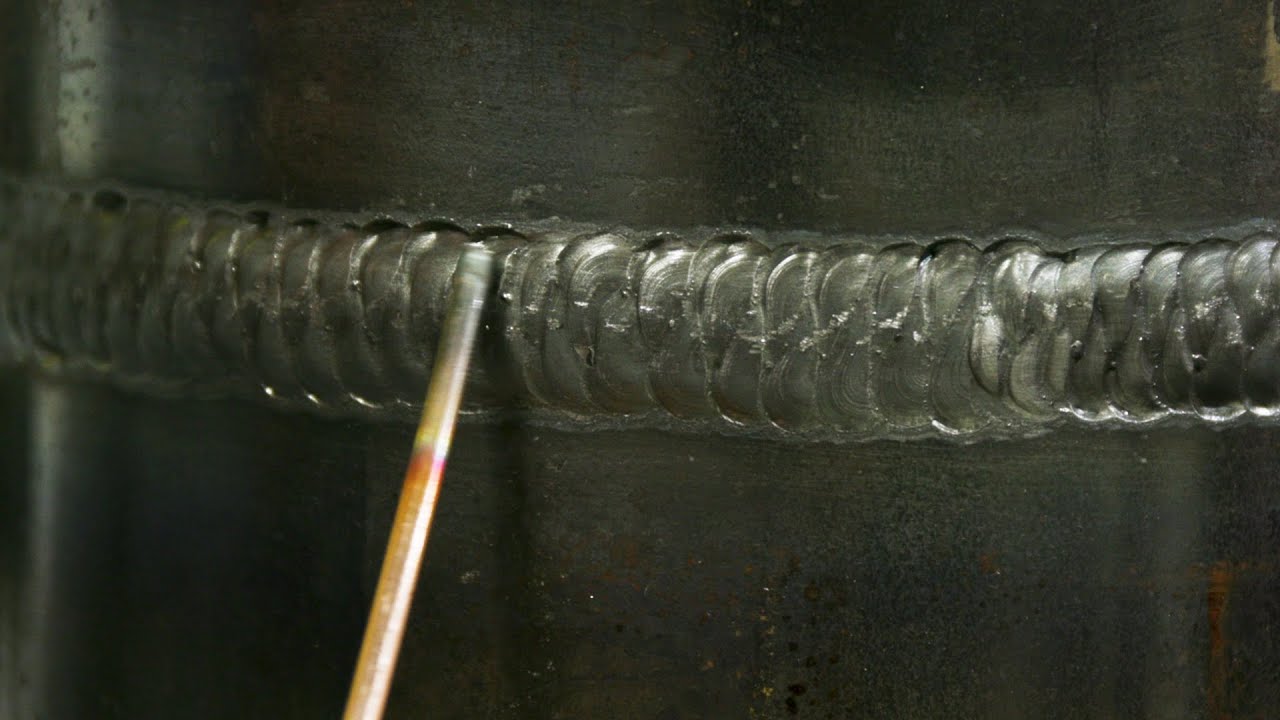

To alleviate the risk of undercutting in welding, welders can employ calculated welding techniques intended at improving the top quality and stability of the weld joints. Additionally, using the proper welding technique for the certain joint configuration, such as weave or stringer grains, can contribute to minimizing undercutting.

Additionally, appropriate joint prep work, including ensuring clean base products totally free of pollutants and making use of the ideal welding consumables, is essential in avoiding undercut problems. Using back-step welding techniques and managing the weld grain profile can likewise aid distribute heat uniformly and decrease the danger of undercut. Routine inspection of the weld joint during and after welding, in addition to executing quality control steps, can help in resolving and spotting undercutting problems without delay. By applying these strategies faithfully, welders can attain perfect manufacture results with minimal undercut flaws.

Relevance of Proper Welding Parameters

Selecting and keeping appropriate welding specifications is essential for attaining effective welds with minimal defects. Welding criteria describe variables such as voltage, existing, travel rate, electrode angle, and protecting gas circulation price that directly affect the welding procedure. These specifications must be very carefully readjusted based on the kind of material being bonded, its thickness, and the welding strategy used.

Appropriate welding specifications make certain the correct amount of warm is related to thaw the base metals and filler material uniformly. If the specifications are set also high, it can cause extreme heat input, causing burn-through, spatter, or distortion. On the various other hand, if the criteria are as well low, incomplete fusion, absence of infiltration, or undercutting might occur.

Quality Control in Welding Workflow

Verdict

In conclusion, understanding the art of welding needs a thorough understanding of undercut welding, its reasons, and strategies to avoid it. By making sure correct welding parameters and carrying out quality assurance methods, remarkable manufacture outcomes can be accomplished. It is necessary for welders to constantly make every effort for quality in their welding operations to avoid undercut issues and create top notch welds.

Undercut welding, a common flaw in welding procedures, occurs when the weld steel does not properly fill the groove and leaves a groove or depression along the bonded joint.To avoid undercut welding, welders ought to guarantee proper welding criteria, such as readjusting the existing, voltage, traveling rate, and keeping the correct electrode angle. Poor welding incorrect or existing welding rate can likewise contribute to damage.To minimize the danger of undercutting in welding, welders can utilize tactical welding techniques aimed at boosting the high quality and integrity of the weld joints.In verdict, page grasping the art of welding needs a detailed understanding of undercut welding, its discover this info here causes, and strategies to stop it.

Report this page